How Are Fountain Pens Made

If you have been wondering how fountain pens are made in a quest to help you better understand this historic writing instrument, you’ve come to the right place.

Discover what goes into the creation of fountain pens from the materials used to the individual steps in making the different parts, and much more.

Let’s begin with an overview of the manufacturing process that defines what a fountain pen is.

How are Fountain Pens Made: the Basic Process

The manufacture of fountain pens follows a simple process.

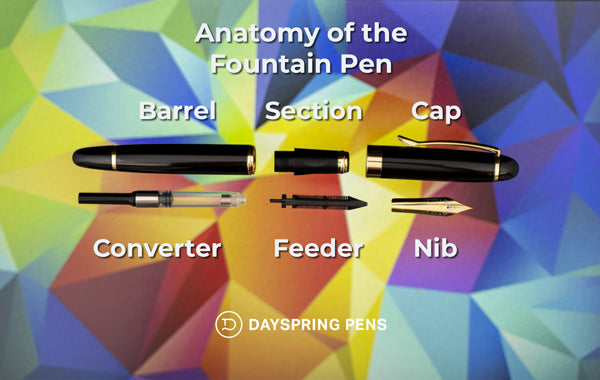

- The formation of the pen body and cap, any decorative additions are crafted.

- Parts like the feed, ink filling system, and converter are made.

- The nib is created and ground to the desired shape.

- Ink is mixed and either used to fill cartridges or bottled.

- All parts are assembled and the pens tested to ensure they work well.

Materials Used in Production

Now, let’s take a look at the materials involved in the manufacturing process of fountain pens and fountain pen ink.

There may be some variations in the process by fountain pen brands, but generally the system is the same.

Overview of Common Materials

Fountain pens are usually made of materials such as:

- Plastic

- Resin

- Ebonite

- Stainless steel

- Gold

- Iridium

- Precious metals

The type of materials used affects the pen's weight, balance, durability, and aesthetic.

Common materials in fountain pen ink

Manufacturers use a mixture of substances to make fountain pen ink, such as:

- Water

- Dyes

- Biocides (which discourage growth of bacteria)

- A variety of other additives like reflective particles for shimmer and pH adjusters for sheen

Generally, the more additives added to the ink, the higher the cost of the ink will be.

The Manufacturing Process

It’s time for a detailed breakdown of the fountain pen creation process.

Step 1: Preparing the Materials

The first step is treating and preparing the materials for molding or shaping, with the process varying with the specific material.

Plastic Components

Plastic undergoes conditioning procedures such as drying to remove moisture and ensure uniform properties.

For plastic resin which is usually in pellet form, the pellets are melted then injected into molds. Colorants, reinforcing agents, and UV stabilizers are added at this stage depending on the qualities the manufacturer wants for the finished product.

Metal Components

Metal components are formed through casting, machining, or forging, depending on the complexity of each part.

After forming, next is treating the surface through processes like polishing, anodizing, or plating to enhance the appearance and improve longevity.

Celluloid and Ebonite Components

Other materials such as celluloid and ebonite receive special treatment such as curing and stabilization before being shaped to avoid cracking or warping.

After preparation, these materials are molded or machined into different shapes. Celluloid is usually injection molded while ebonite is turned on a lathe.

The final step is polishing to achieve a smooth finish and remove any imperfections.

Step 2: Barrel and Cap Creation

The barrel and cap of fountain pens are formed through different methods depending on whether the pens are artisanal or mass produced.

For artisanal fountain pens, traditional methods of handcrafting such as turning on a lathe are used. Artisans carefully shape and polish materials like resin, precious metals, and celluloid to create custom designs.

Throughout the process, they ensure the highest attention to detail to achieve the desired standards.

Factory-made fountain pens, on the other hand, are usually made through automated processes. Plastics and metal alloys are shaped by molding or machining.

At this point, features such as grooves for screw-on sections, threads for screw-on caps and decorative elements are added into the design.

The final step is to polish the barrel and cap for enhanced visual appeal.

Extra Info: Find out How Ballpoint Pens are Made

Step 3: Making the Fountain Pen Nib

Fountain pen nibs are made of different metals such as gold, stainless steel, or titanium, with each giving varying degrees of flexibility and aesthetic appeal to the nib.

Creation of the nib begins with cutting the metal into the basic nib shape through cutting, stamping or machining. For intricate designs, Computer Numerical Control (CNC) machines are used to achieve precise shapes.

Next, the tipping material is attached to the end of the nib using welding or adhesive bonding.

Hard-wearing metals such as osmium, iridium, and tungsten mixed into alloys are used for nib tips to provide a smooth writing surface and maintain the nib’s structural integrity over time.

The nib is then ground and polished to smooth out rough edges and refine its shape.

Step 4: Fountain Pen Ink Mixing

This step involves several processes to create the right color, consistency, and performance characteristics of the ink:

Color Formulation

Manufacturers begin by creating the ink colors using a combination of dyes and pigments to achieve specific hues. They either mix primary colors or use ready-made color concentrates.

Ingredient Preparation

Once the formulation is done, it’s time to get the ingredients ready. Several methods to achieve this include:

- Grinding pigments to the correct size

- Diluting color concentrates

- Measuring additives such as biocides

- Ingredient mixing

The ingredients are then blended together in a controlled environment to ensure consistency. High-speed stirrers in the mixing vats ensure that the components get distributed evenly for a homogenous ink mixture.

Adjustments and Testing

Monitoring of the intensity, pH, and viscosity takes place throughout the mixing process and adjustments are made as needed. Through quality control tests, the manufacturer ensures the fountain pen ink meets the set standards for flow, color accuracy, and other properties.

Ink Filtration

This involves removing impurities from the mixture to ensure the ink moves smoothly through the fountain pen without clogging the reservoir or nib.

After filtration, the ink is refined to remove air bubbles and achieve optimum stability.

Step 5: Ink Filling Mechanisms

Fountain pens come with different types of filling systems, each having its own method of assembly.

The most common filling systems are:

- Cartridges and Converters

- Piston Fillers

- Eyedropper Systems

- Vacuum Filling Systems

- Bladder/Rubber Sac Systems

Cartridges and converters are all made and assembled separately from the pen.

Piston, vacuum, bladder, and eyedropper systems are all built into the body of the pen, making the entire barrel the ink reservoir.

Step 6: Assembly

After all the components are ready, they are all brought together to ensure a tight fit and prevent leaks. This includes two main procedures:

Fixing the nib onto the pen barrel

The nib and feed are carefully inserted into the grip section of the pen body. Depending on the fountain pen’s design, the nib is threaded or friction fit to hold it in place.

In addition, the nib is aligned with the feed to ensure proper ink flow.

Attaching the cap and clip

This usually involves screwing the cap onto threads at the end of the pen barrel. The cap protects the nib when the pen is not in use, and enhances the pen’s aesthetic.

For pens that have one, the clip is attached to the cap at this point. The clip may be riveted, soldered, or mechanically fastened in place.

The table below compares key features of some of our favorite fountain pens:

| Fountain Pen Model | Barrel & Cap Material | Nib Material | Nib Size | Refill System |

| Dayspring Pens Alexandria | Lacquer, gold | Stainless steel | Medium | Cartridge/Converter |

| Waterman Expert | Brass, lacquer | Stainless steel, gold | Fine, medium | Cartridge/Converter |

| Waterman Hemisphere | Brass, lacquer, palladium | Stainless steel, gold | Fine, medium | Cartridge/Converter |

| Cross Century II | Lacquer, gold | Gold | Fine, medium | Cartridge/Converter |

Handmade Fountain Pens

Not all fountain pens are produced in factories—some are made through handcrafting.

Artisanal pens are characterized by attention to detail and the use of traditional techniques.

Either individual craftsmen or small teams of artisans handle the creation of these fountain pens through processes such as hand-engraving, turning on a lathe, and hand-polishing to create unique pieces.

They are produced in small batches or as one-of-a-kind, and each pen receives personal attention from the artisan.

What’s more, these fountain pens are often sold through boutique shops, specialized retailers, or in artisan workshops, further elevating their exclusivity.

In contrast, machine-made pens are made in large quantities using automated procedures. This results in standardization with less variation in the designs, but decreased how much fountain pens cost.

Quality Control and Testing

Fully assembled fountain pens go through rigorous testing to check their functionality and quality. Typical tests include checking the consistency of ink flow, the nib’s smoothness, and performance of filling mechanisms such as cartridges.

If needed, adjustments and fine-tuning are done to the pens to ensure a smooth writing experience.

Pens that pass the inspection process get packed for distribution, with some pens even coming with certifications that verify their quality.

Fun Fact: the Parker 75 undergoes more than 700 inspections. Its certificate of quality is signed by the final inspector.

The Harmony Between Tradition and Innovation in Fountain Pen Design

The balance between tradition and innovation in the fountain pen industry manifests itself in different ways. Let’s look at some of them below.

Traditional aesthetics with modern materials: Many manufacturers carry on the classic design elements of traditional fountain pens, for instance intricate detailing and sleek profiles. At the same time, they incorporate modern materials like resins for durability and aesthetics.

Customization: Modern fountain pen enthusiasts like to express their individuality through personalized designs. To meet this need, brands leverage traditional crafting methods alongside innovative techniques like 3D printing and laser engraving.

This allows users to customize their pens while maintaining traditional elegance.

Innovation in nib technology: Traditional designs such as gold nibs with iridium tips remain popular for their smoothness. Even so, manufacturers continue to develop specialized nib alloys and advanced feed systems.

These innovations enhance the writing experience while preserving traditional nib craftsmanship.

Refill mechanisms: Modern fountain pens have more user-friendly and efficient filling systems compared to the early versions of traditional pens. Advancements in refill mechanisms like converters and piston fillers allow for improved ink capacity and ease of use.

Conclusion

The fountain pen manufacturing process involves a range of materials, processes, and technologies. Understanding how these pens are made builds a deeper appreciation for them as important writing instruments.

Whether you prefer meticulously handcrafted artisanal fountain pens or their factory-made counterparts, each pen tells a unique story with its functionality and aesthetic.

Even with advancements in innovation, manufacturers continue to pay homage to the essentials of traditional pens. While technology opens new possibilities in using different materials, traditional design elements and craftsmanship are still preserved.

Fountain pens continue to stand as symbols of creativity, craftsmanship, and self-expression in today’s increasingly digital world. Whether used for everyday writing or valued as collectibles, fountain pens captivate enthusiasts with their functionality and beauty.

|

Sam Di Nardo is an author for Dayspring Pens, where she has honed her expertise in ballpoint, rollerball, gel and fountain pens since joining the team in 2018. From her initial role as an Engraver to becoming the Production Manager, Sam's journey has been marked by her passion for the history, manufacturing, and the unique value of gifted writing instruments. A graduate of Regent University with a degree in English Literature and a special interest in Old Norse literature, dive deeper into Sam's world and discover why she's your trusted guide in the realm of gift pens. |

Share